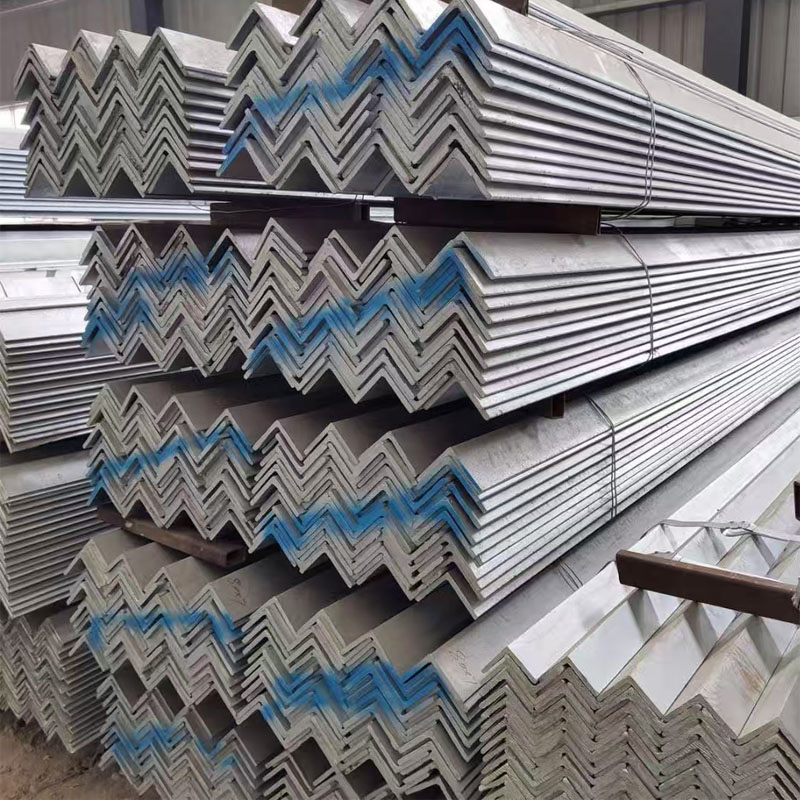

Q235B/Q355B Galvanized angle iron

Q235B and Q355B galvanized angle steel are two common steel materials for construction and structure. They have some differences in chemical composition, mechanical properties, and uses.

Q235B and Q355B galvanized angle steel are two common steel materials for construction and structure. They have some differences in chemical composition, mechanical properties, and uses.

Q235B steel plate has high yield strength and tensile strength, with a yield strength of 235MPa and a tensile strength between 370 and 500MPa. It can withstand large loads and provide a solid structural foundation for angle steel, allowing it to withstand certain pressure and tension during use. Q235B is easy to cast and weld, which is conducive to the manufacture of angle steels of various shapes, and during the processing and assembly process, it is easy to connect with other parts by welding and other methods. In addition, it also has good plasticity and is easy to carry out processes such as cutting, bending, and stamping.

These types of angle steels are galvanized. The galvanized layer can provide the angle steels with good anti-rust and corrosion resistance, greatly extending the service life of the angle steels in different environments, and are especially suitable for environments with humid and corrosive media.

A36 and A572 Grade 50/60/65 are common structural steel materials, which are widely used in buildings, bridges and other structures.

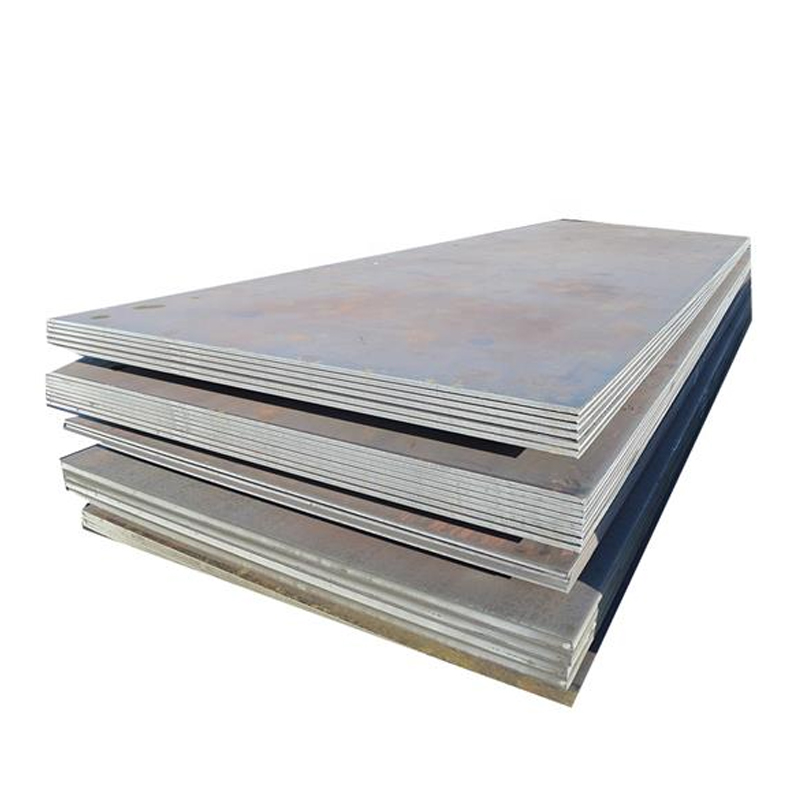

High precision: Cold rolled steel plates have more precise thickness and high dimensional accuracy, which can meet the needs of various precision machining. Superior performance: It has good mechanical properties such as high strength and hardness, as well as a certain degree of toughness, which can meet the requirements of different application scenarios.

Our hot-rolled carbon steel plates are manufactured from high-quality carbon steel raw materials through a continuous rolling process at temperatures above the recrystallization point. Although the surface of the product exhibits a natural scale color due to oxidation, its internal structure is uniform and dense, with excellent grain refinement, endowing it with outstanding toughness and ductility. With the combined advantages of high strength and good plasticity, it can not only withstand significant mechanical stress but also easily meet the forming requirements of complex components through processing methods such as bending and stamping.