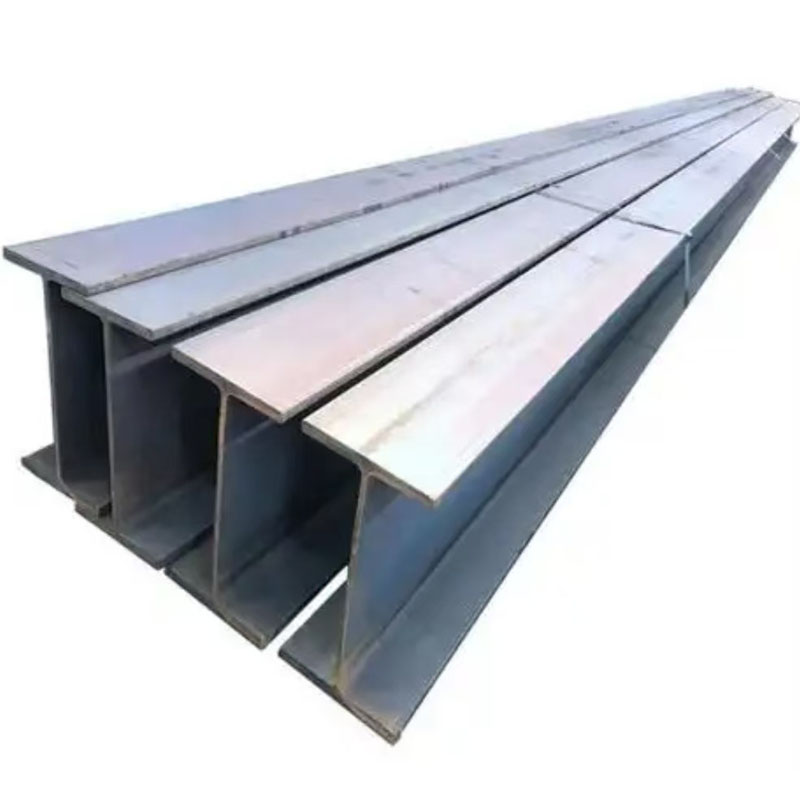

Steel bars are a fundamental component in construction, widely used to reinforce concrete structures. But what exactly are they made of? Today, we delve into the key materials that constitute steel bars and their role in ensuring strength and durability.

Primary Components of Steel Bars:

Steel bars, also known as rebars, are primarily composed of iron (Fe) and carbon (C), with additional alloying elements to enhance performance. The exact composition varies depending on the grade and application, but the main constituents include:Iron (Fe) – The base metal, providing the fundamental structure of the steel.

Carbon (C) – Typically ranging between 0.05% to 2%, carbon increases hardness and strength but reduces ductility if present in high amounts.

Manganese (Mn) – Improves strength and workability, usually present in 0.5% to 1.5%.Silicon (Si) – Enhances strength and removes oxygen during production (commonly 0.15% to 0.3%).Sulfur (S) & Phosphorus (P) – Usually kept below 0.05% as they can weaken the steel and cause brittleness.

Alloying Elements for Specialized Rebars:

Some high-strength steel bars include additional elements such as:

Chromium (Cr) – Improves corrosion resistance.

Vanadium (V) & Nickel (Ni) – Increase tensile strength and toughness.

Copper (Cu) – Enhances weather resistance in certain environments.

Why Does Composition Matter?

The precise proportioning of these materials determines a steel bar’s yield strength, ductility, weldability, and corrosion resistance, making them suitable for diverse construction needs—ranging from residential buildings to bridges and skyscrapers.

At the micro level, the carbon content directly influences yield strength: higher carbon content typically enhances yield strength but reduces ductility. Alloying elements such as manganese and silicon can optimize the steel’s toughness and weldability while increasing its strength, while elements like chromium and nickel strengthen corrosion resistance by forming a dense oxide film on the surface to withstand external erosion. This combination of performance variations allows steel bars to adapt to construction projects of different scales and functions.

For example, ordinary residential buildings require steel bars with relatively lower strength but prioritize economy and basic load-bearing capacity. In contrast, cross-sea bridges and super-high-rise skyscrapers demand high-strength, tough, and corrosion-resistant steel bars to withstand complex geological conditions, strong wind loads, and harsh environmental factors.