1. Construction Industry

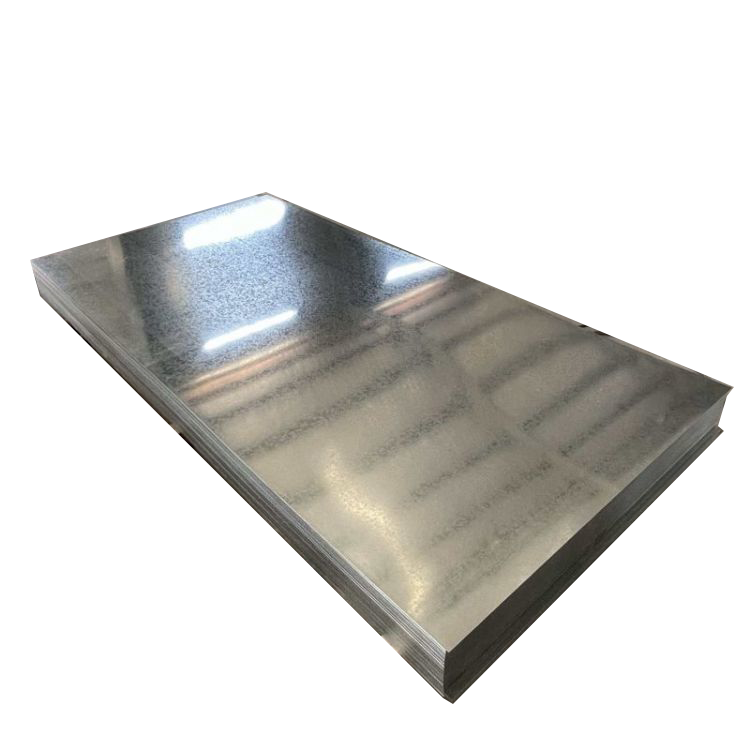

Building Envelopes: Used for roofing, wall cladding, and siding in commercial, residential, and industrial buildings.

Prefabricated Structures: Ideal for prefab houses, warehouses, and sheds due to its lightweight and easy installation.

Decoration: Provides decorative finishes for exterior and interior architectural elements (e.g., cornices, partitions).

2. Home Appliances

Appliance Shells: Manufactures casings for refrigerators, washing machines, air conditioners, and kitchen cabinets, combining durability with visual appeal.

Interior Decor: Used in kitchen countertops, furniture panels, and decorative trims.

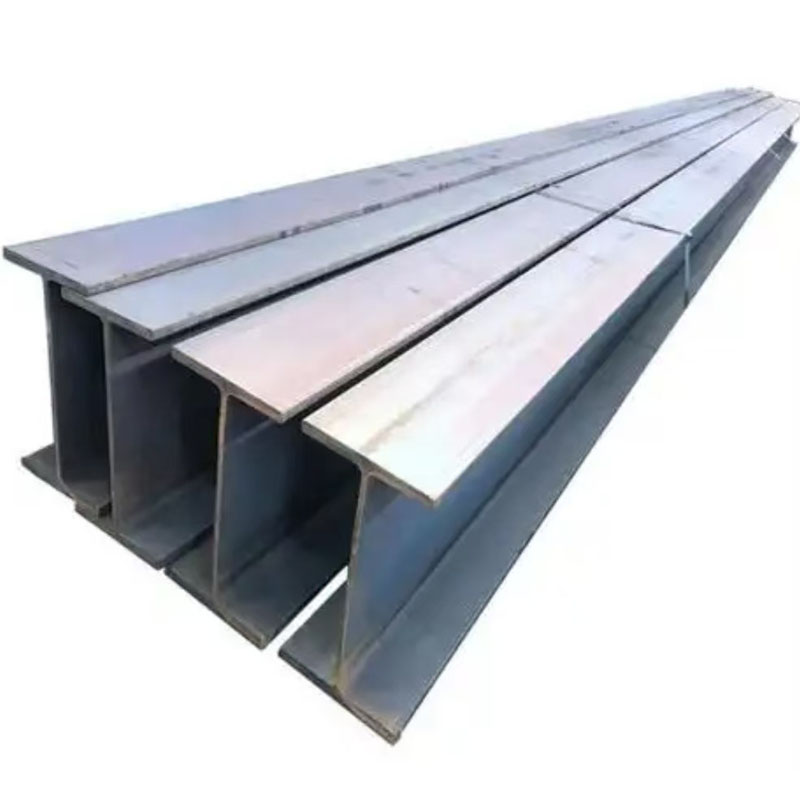

3. Transportation Sector

Vehicle Body Parts: Applied to truck bodies, trailers, and container exteriors for corrosion protection.

Railway & Metro Cars: Used in interior panels and exterior cladding for lightweight and fire-resistant properties.

4. Electronics and Furniture

Electronics Enclosures: Makes shells for computers, TVs, and other electronic devices.

Furniture Components: Used in office furniture, storage cabinets, and shelving for a sleek finish.

5. Packaging Industry

Metal Cans and Containers: Produces food and beverage cans, paint buckets, and chemical containers with anti-rust properties.

6. Energy and Infrastructure

Solar Panel Frames: Provides durable supports for solar installations.

Power Equipment: Used in enclosures for transformers and electrical cabinets.

7. Specialized Applications

Marine and Coastal Projects: Corrosion-resistant coatings for structures in high-humidity or saline environments.

Advertising Signage: Manufactures billboards, signboards, and display panels for weather resistance.

Key Advantages Driving Its Use:

- Corrosion Resistance: Protective coatings prevent rust, extending service life.

- Design Flexibility: Available in various colors, textures, and finishes for aesthetic customization.

- Cost Efficiency: Reduces post-processing costs (e.g., painting) and minimizes maintenance needs.

- Environmental Friendliness: Some coatings use eco-friendly materials, meeting sustainability standards.