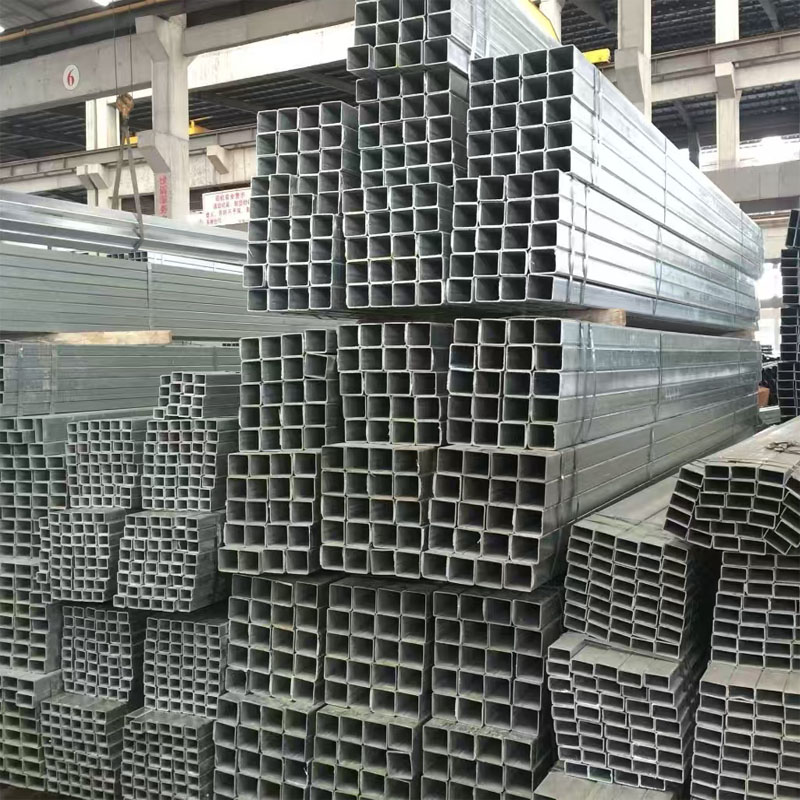

S235JR/S275JR/S355JR/S355JO Galvanized square pipe

S235/S275/S355/JR/JO galvanized square tube is a kind of steel widely used in construction, structural engineering and various industrial fields.

S235/S275/S355/JR/JO galvanized square tube is a kind of steel widely used in construction, structural engineering and various industrial fields.

American standard square pipe A500 Grade B, C, and D all adopt the A500 standard issued by the American Standards Association (ASTM), which means that they meet internationally recognized standards in terms of quality and performance. It can be widely used in building structures, machinery manufacturing and other fields.

Galvanized angle steel is a specific type of galvanized steel. Galvanized steel is a steel material that has been galvanized. Galvanizing is a technology that coats the surface of steel with a layer of zinc. This layer of zinc can prevent the steel material from corrosion.

Q235B is a carbon structural steel with a chemical composition of carbon (C) ≤ 0.22%, manganese (Mn) ≤ 1.4%, silicon (Si) ≤ 0.35%, etc. In the national standard GB700-88, Q235B material is often subjected to temperature shock tests, V-notch, and carbon content between 0.14 - 0.22﹪.

After hot-dip galvanizing, a zinc layer is formed on the surface of the steel. This zinc layer can effectively isolate the steel from the external environment, prevent oxygen, moisture, etc. from corroding the steel, and greatly extend the service life of the angle steel. It is especially suitable for humid and corrosive environments, such as seaside buildings, chemical plants, etc.

American standard H-beam A36 is a carbon structural steel with excellent performance. It is made by adding a certain amount of alloy elements such as silicon, manganese, phosphorus, etc. to ordinary low-carbon steel. Its main component is iron, the carbon content does not exceed 0.2365%, the silicon content is between 0.15% - 0.40%, the manganese content is between 0.30% - 0.60%, and the phosphorus content is between 0.035% - 0.045%. The reasonable ratio of these elements makes A36 have excellent performance in strength, hardness and toughness. It also has excellent plasticity and weldability.