Rebar

ribbed steel bar, as a core foundation material in the field of construction, has become a reliable guarantee for various engineering constructions due to its excellent performance and wide applicability.

ribbed steel bar, as a core foundation material in the field of construction, has become a reliable guarantee for various engineering constructions due to its excellent performance and wide applicability.

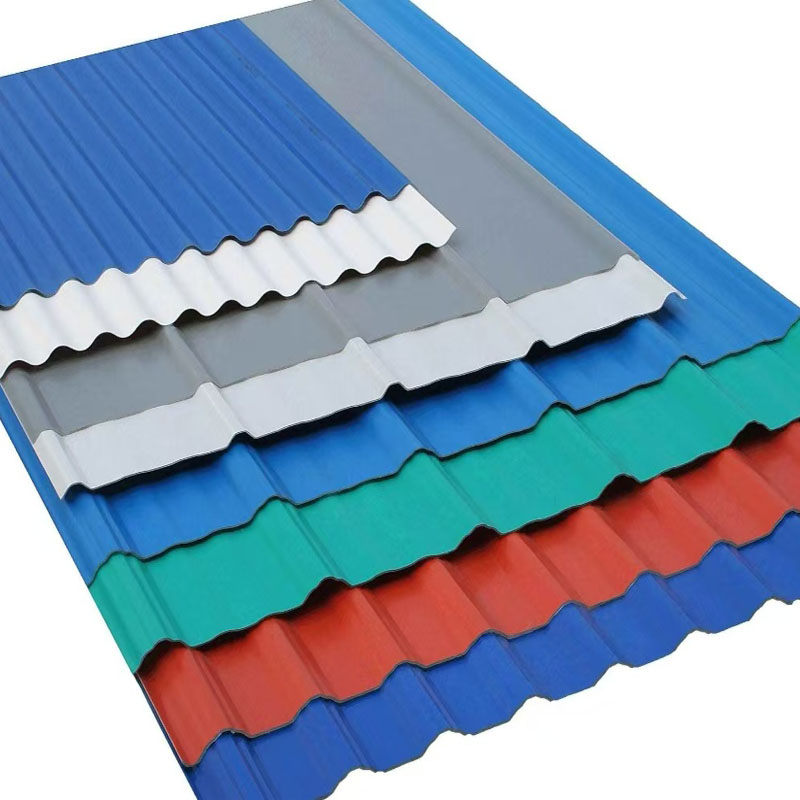

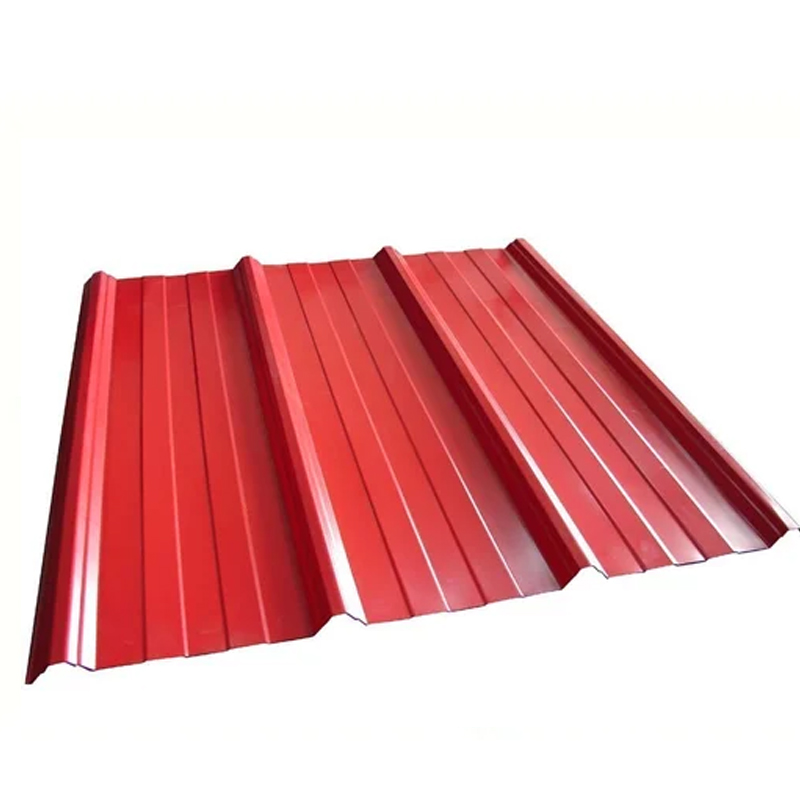

It is corrugated, which increases the strength and rigidity of the sheet, making it more stable when subjected to pressure and weight. It is treated with processes such as galvanizing and color coating. The galvanizing process can improve the corrosion resistance of the sheet, and the color coating gives the sheet rich colors and beautiful appearance, while further enhancing its protective performance. There are many surface treatment methods, such as anti-rust paint, varnish, galvanizing, 3LPE, 3PP, zinc oxide yellow primer, zinc phosphate primer, etc., which can be selected according to customer requirements.

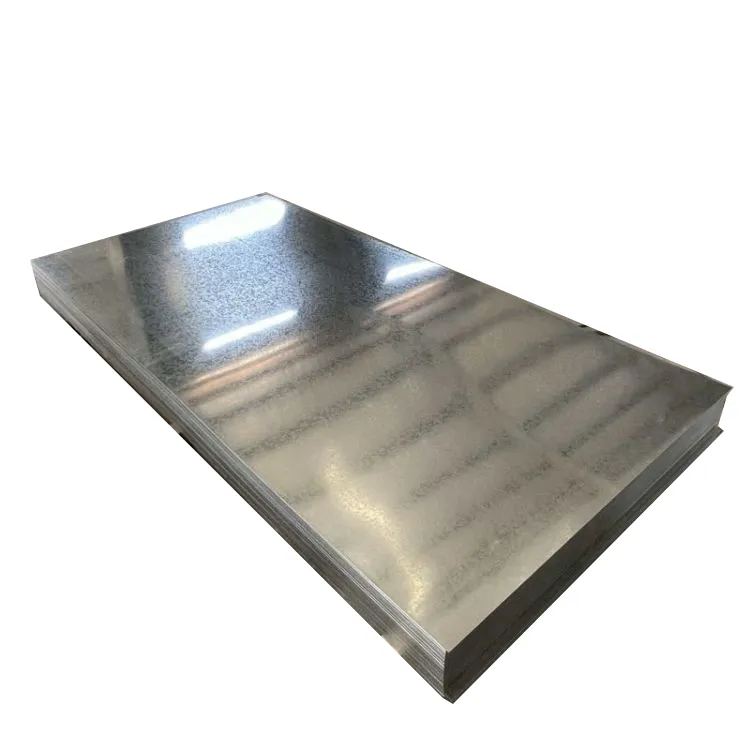

The galvanized layer can effectively prevent oxygen from contacting the metal surface, thereby slowing down the oxidation rate of the metal and improving the corrosion resistance of the galvanized sheet, so that it can be used for a long time in harsh environments without rusting, reducing the frequency of maintenance and replacement.

In terms of materials, there are stone-coated metal materials, which are natural stones coated on metal plates, as well as galvanized steel plates, aluminum-zinc alloy steel plates, etc.; the thickness generally ranges from 0.12 - 0.6mm (±0.02mm), for example, there are 0.30 - 0.60mm, 0.14/0.15/0.16mm and other different thicknesses; there are various sizes and a variety of corrugated styles and standard specifications

The distinctive corrugated design not only adds structural rigidity, enabling the material to bear heavy loads and resist deformation, but also channels rainwater efficiently, preventing pooling and leaks.

Color coated roof tiles are usually made of ZINCALUME coated steel with a thickness of 0.4 mm and an aluminum-zinc coating of up to 150 g/m2, which has excellent rust resistance. In addition, stone particles cover the steel surface, further extending the service life. With the T-Lock installation method, one roof tile can be connected to the surrounding six tiles to form a very stable module, so it is usually available with a warranty of up to 50 years.