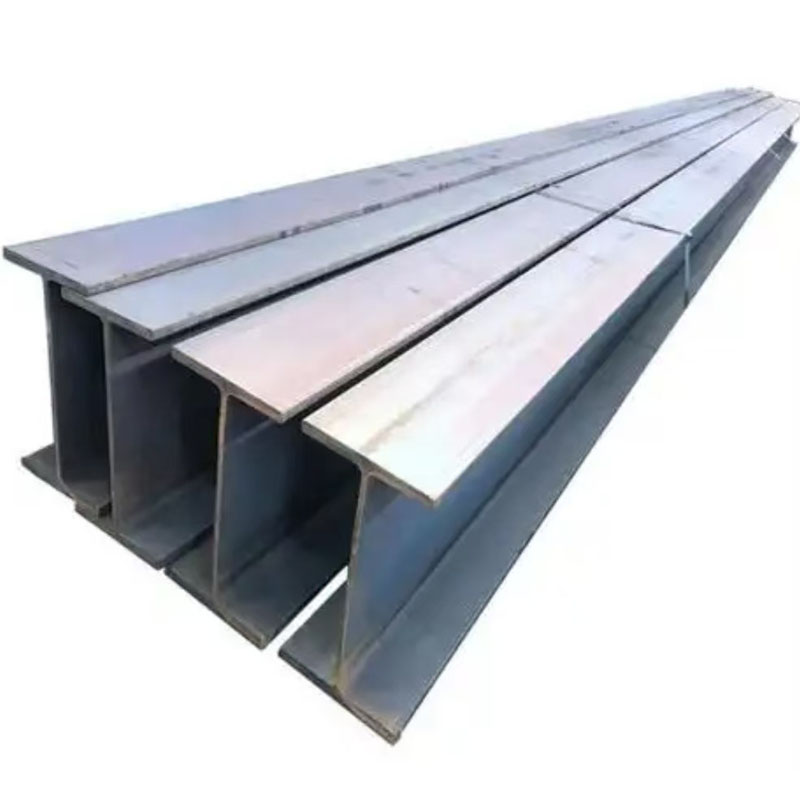

Mechanical rebar joining is the third generation of rebar joining processes, following tying and electric welding. It offers advantages such as joint strength exceeding that of the parent material, rapid construction, zero pollution, and reduced steel consumption. Its core principle is to achieve equal strength connections between rebars through mechanical interlocking, primarily used in construction projects.

This technology is divided into three types: sleeve extrusion, tapered thread, and straight thread. Sleeve extrusion, which interlocks a radially extruded steel sleeve with the rebar, has been widely used in my country since the 1990s. Tapered thread has been gradually phased out due to insufficient joint strength. Straight thread connections are divided into upsetting and rolling. Rib stripping and rolling straight thread technology, which pre-treats the ribs at the rebar ends, achieves high thread precision and strong assembly stability. It is suitable for applications with high strength, high ductility, and fatigue resistance. Developed by the China Academy of Building Research, it has been expanded to various rebar specifications.

In the history of technological development, sleeve extrusion was the primary process in the early days, but after its introduction in the 1990s, it was gradually replaced by straight thread technology. Straight thread connections have become the international mainstream due to their balance of strength and construction efficiency. Building on this strength, my country has developed an innovative rib-peeling rolling process to further enhance joint performance, meeting the requirements of specialized structures such as airports and bridges. Joint performance must meet regulatory standards for tensile strength, residual deformation, and elongation.